A rural South Carolina knife maker hones his talents while creating highly sought-after culinary tools.

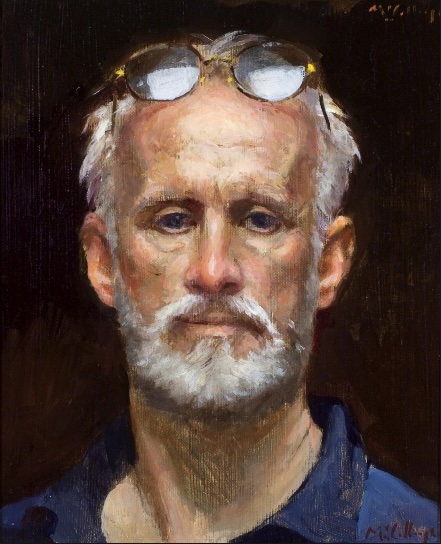

Quintin Middleton is tenacious, a man who developed a passion, cultivated it, pursued it relentlessly, and made something incredible of his life, reaching and inspiring people near and far with his talent and story. As the skilled artisan behind Middleton Made Knives, Middleton makes high-quality chef knives for some of the top names in the business. Driven and dedicated, he is one to watch as he ascends higher into his personal and professional successes.

Currently a resident of St. Stephen, Middleton was born and raised in rural South Carolina. After high school, he began pursuing further education to be an aircraft mechanic while working at a knife and cigar shop in Northwoods Mall. One fateful day, Master Bladesmith Jason Knight came in to purchase a katana. The two struck up a conversation, and Quintin Middleton learned that Jason Knight made knives for a living. Middleton had always fostered a passion for knife and sword making, but assumed it would, at best, remain a hobby. For the first time, it struck Middleton that one could support a life and family as a knifemaking artisan. Recognizing an opportunity to learn from a master, he asked Knight if he could teach him how to make knives. Knight was reserved about offering free lessons to a relative stranger, and told Middleton that he could come to the house to observe, which Middleton did with great enthusiasm. At Knight’s workshop, the bladesmith gave Middleton a piece of steel to make a knife, in an effort to gauge the younger man’s skill level. Middleton quickly produced a sword, proving to Knight that while he had much to learn, he was a self-taught, eager apprentice. Indeed, Middleton had already set up shop in a shed at his mother’s house in Alvin, South Carolina, where he would practice techniques until his fingers were numb. Located right next to his mother’s washing machine and dryer, the makeshift workshop created a mess all over the clean clothes every time Middleton sharpened or ground metal, but his family supported his work all the same, no matter how skeptical they may have felt at the beginning.

“I’d get inspiration, and I’d run out in my robe and just start grinding away,” Middleton remembers. “A lot of people thought I was crazy, but no one tried to stop me. They knew I was passionate about it.”

In Jason Knight’s workshop, Quintin Middleton soaked in any and all advice the Master Bladesmith was willing to share while he worked metal into beautiful blades. Middleton watched every move Knight made, asking questions and taking mental notes on techniques and tools used. Often, he found himself back in his own workshop after visiting with Knight, perfecting skills and attempting new ideas. After a year of hosting Middleton as an observer, getting to know him, and taking him in as a brother, Knight finally trusted the young man on his powerful machines, and Middleton’s skills flourished. For the next few years, the pair often worked side by side, creating, learning, and sharing while working on hunting knives, swords, and the like. Eventually, Middleton found his own path in the world of bladesmithing and knifemaking. As a minister and deeply spiritual man, Middleton has always found truth in dreams, and this time, it was no different.

“Right before I got married,” Middleton remembers, “I had a dream. God told me to make chef’s knives. I said, ‘Ok God, but how do I make them?’ It was never my focus, so I didn’t even know where to start at first.”

Middleton quickly came up with a plan. He began poring over photos of chef’s knives, saving the ones that were visually appealing to him. Then, he made a long list of chefs in Charleston, and called every last one of them, offering to make and sell them a custom knife. Each and every one of them turned him down. Middleton was disheartened, but never one to accept defeat, he tried a new strategy. He called Chef Craig Deal at Cypress Restaurant for the second time that day, and quickly explained his vision: to make the highest quality locally made chef’s knives Charleston had ever seen. Middleton asked Deal if he would be willing to help develop a knife, and Deal agreed, asking him to come in on a particular date and time. Middleton was thrilled, and channeled his exuberance into his work, producing a set of the best chef’s knives he could make. He brought them to Cypress Restaurant and presented them to Chef Deal and his team, and…it didn’t go well.

“They looked like disappointed kids on Christmas,” says Middleton. “They were picking up the knives and quickly putting them down, saying they were cool while their eyes said something completely different. I asked Chef Deal what he honestly thought, and he said he didn’t like them. He said they were too heavy, too thick, and the balance was completely off. It was tough to hear, but I needed it. I was an amateur, and he was giving me real talk to help me improve.”

With the feedback of the kitchen team in mind, Middleton went back to his workshop to create a new prototype. He brought it back to Chef Deal, who admitted it was an improvement, but that it still needed work. The process repeated until finally, Middleton produced a knife that made all of the kitchen staff happy. It was swiftly purchased by one of the Cypress team members, and Middleton walked out feeling like a million dollars. Chef Deal and the rest of the kitchen staff began to spread the word about Middleton’s knives to their friends in Charleston, and suddenly, Middleton was being talked about all over town. A locally-based regional magazine reached out, and the interview catapulted him to fame. He started getting orders to make knives for famous chefs, including Emeril Lagasse, Guy Fieri, Mario Batali, and of course, Sean Brock. No matter who placed an order, Middleton took the same great care and attention to detail, crafting a high carbon steel knife to their exact specifications. For Middleton, the long road to success resulted in something past his wildest dreams, but those who love him were unsurprised.

“In the middle of trying to make all of this work, I lost my full time job and then, my second child was born,” remembers Middleton. “We were barely making ends meet. I wanted to just throw myself into the knifemaking and use it to support us, but I wasn’t sure I would be able to make it work financially. I said to my wife, ‘Babe, I don’t know if I can do this.’ And she said, ‘You believe in yourself, and I believe in you. Go for it.’ So I did.”

Middleton’s mother is also one of his strongest supporters. From the beginning, when the metal dust from his grinder was covering all of her freshly-laundered sheets, to now, when he’s being interviewed for international magazines and rubbing elbows with culinary elite, she has always been by his side. Her support led to her making custom sheaths for Middleton’s knives, which are as beautiful as they are functional. For Middleton, the sheaths handmade by his mother reinforce the ethos of his mission.

“I want everything regarding my knives to feel personal,” he explains. “I spend so much time with each piece, turning it over in my hands and working on it until it is perfect. Then, my mom makes the sheath. From our perspective, it really feels like our family is sending you love, and in that way, I hope the love touches as many people as possible.”

Now, seven years after Middleton truly began his journey, his business is a household name in many important circles. He has been featured in Entrepreneur Magazine, Ebony Magazine, Vogue Italy, Tasting Table, Food and Wine Magazine, Saveur Magazine, and more. His creations stock the knife rolls of some of the greatest chefs in the world. He has branched out, offering beautiful oyster knives and unveiling a new economy line this past fall. The new line, called “Echo,” makes Middleton-designed knives more affordable for chefs of all skill levels. The expansion is another step toward a long-held dream of Middleton’s: to eventually be able to build a factory and employ people in his community.

“I want to continue to build my brand and notoriety to the point that it can support a factory,” says Middleton. “Your reputation speaks for itself, and I want the type of reputation where people will support a decision like that, because they know I will follow through. I am confident I’m headed that way.”

In the nearer future, Middleton hopes to open a brick and mortar store in Charleston or Summerville, where he will sell his products and offer knife sharpening services. With his outgoing and personable demeanor, awe-inspiring talent, and focused mind, the sky’s the limit for Quintin Middleton.

By Jana Riley